Micro-torque and position control solution

MODU-spin is a micro-torque and position measurement module. Conceived to be compact and easy to use, it provides a measuring range from 0 up to 60 mNm, with a resolution of 0.1 mNm.

Accuracy and repeatability are ± 5% (less than ± 1.5 mNm), and angular resolution is less than 0.1°.

This module, which can be integrated on our CIMOD AS4 automatic machines, our semi-automatic workbenches, as well as on tabletop stations, allows a dynamic torque and/or position control.

MODU-spin is designed to be used in different sectors, such as watchmaking, medical or electronics.

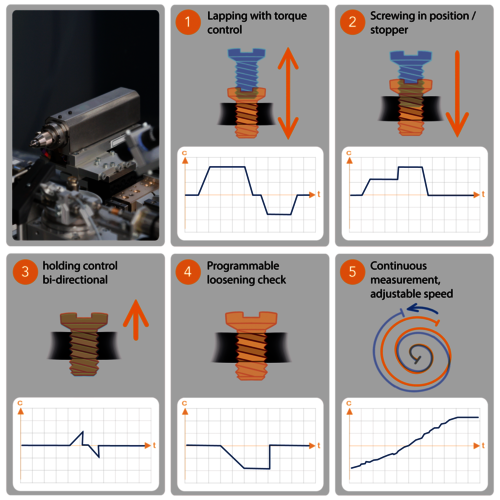

Functionalities

- Lapping with torque control

- Screwing / unscrewing

- Screwing in position / stopper

- Precise end position setting

- Non-destructive withstand measurement

- Loosening check

- Position monitoring according to torque application

- Continuous measurement

- Torque measurement over several revolutions

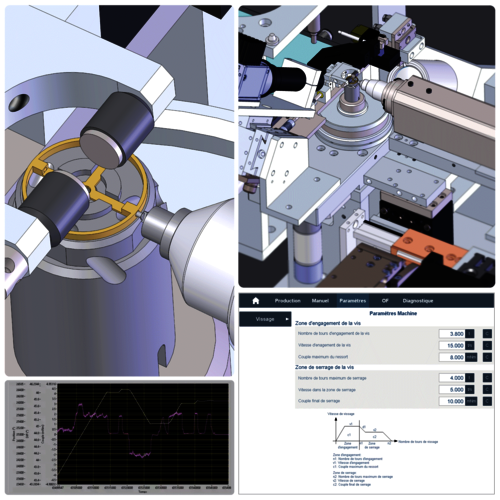

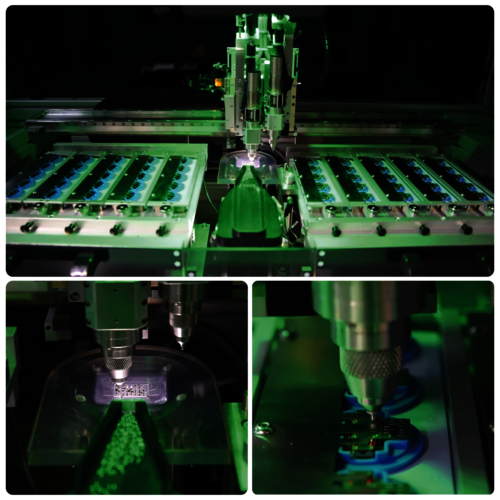

EXAMPLE OF APPLICATION ON AN AUTOMATIC MACHINE

Screwing in four balance screws.

This automatic screw assembly machine project is structured as follows.

Balance wheels are packaged in trays, handling them from bulk would have been possible too.

The 4 screws are fed from the bulk, using a Modufeed, a smart feeding module with an embedded vision system. The vision system identifies which screws are in the correct position to be picked by the vacuum head. The gripper then transfers the screw to the screwdriver tool, centered on balance wheel thread.

The whole screwing process is controlled in position by a vision system, which monitors the position of the screw in regard to the ring mass of the balance wheel.

The screwing process is also torque-servo controlled. This allows to detect possible chip formation and ensures the aesthetics of the component.

Once the screw is in final position, a torque is applied progressively, so that the screwing head detects the minimum applied torque to rotate the screw (withstand torque).

An oiling screw station, placed before the screwing is available as an option, as well as a chip check and cleaning after screwing.

Another option allows, with the addition of an extra Modufeed, to feed and screw in decorative screws.

Components:

- Balance screw Ø thread/head: 0.450/0.500mm

Balance wheel

Features:

- Measuring range: 0 - 10 mNm

- Measuring resolution: 0.1 mNm

EXAMPLE OF APPLICATION ON A SEMI-AUTOMATIC MACHINE

Screwing bench of a motor onto a PCB for quartz watches.

The motors and PCBs are manually loaded into trays of 25 components each, in masked time.

The operator unloads the two trays with the assembled parts and replaces them by two trays of parts to be assembled in position 1, while the machine works with the components from position 2.

The vision system gives the angular position of the screw head, so the screwdriver is oriented and does not injure the screw head when screwing (the screw head does not rub on the screw surface).

The screwing is torque monitored and position controlled by counting the number of revolutions. The cycle ends with the control of the minimum loosening torque.

Components:

- S0.8 screw

Features:

- Measuring range: 0 - 30 mNm

- Measuring resolution: 3 mNm

- Double screw head

- Screws supplied by Modufeed®.

- Dynamic torque control with graphic display