BANC INTELLIGENT ASSEMBLAGE CONTRÔLÉ

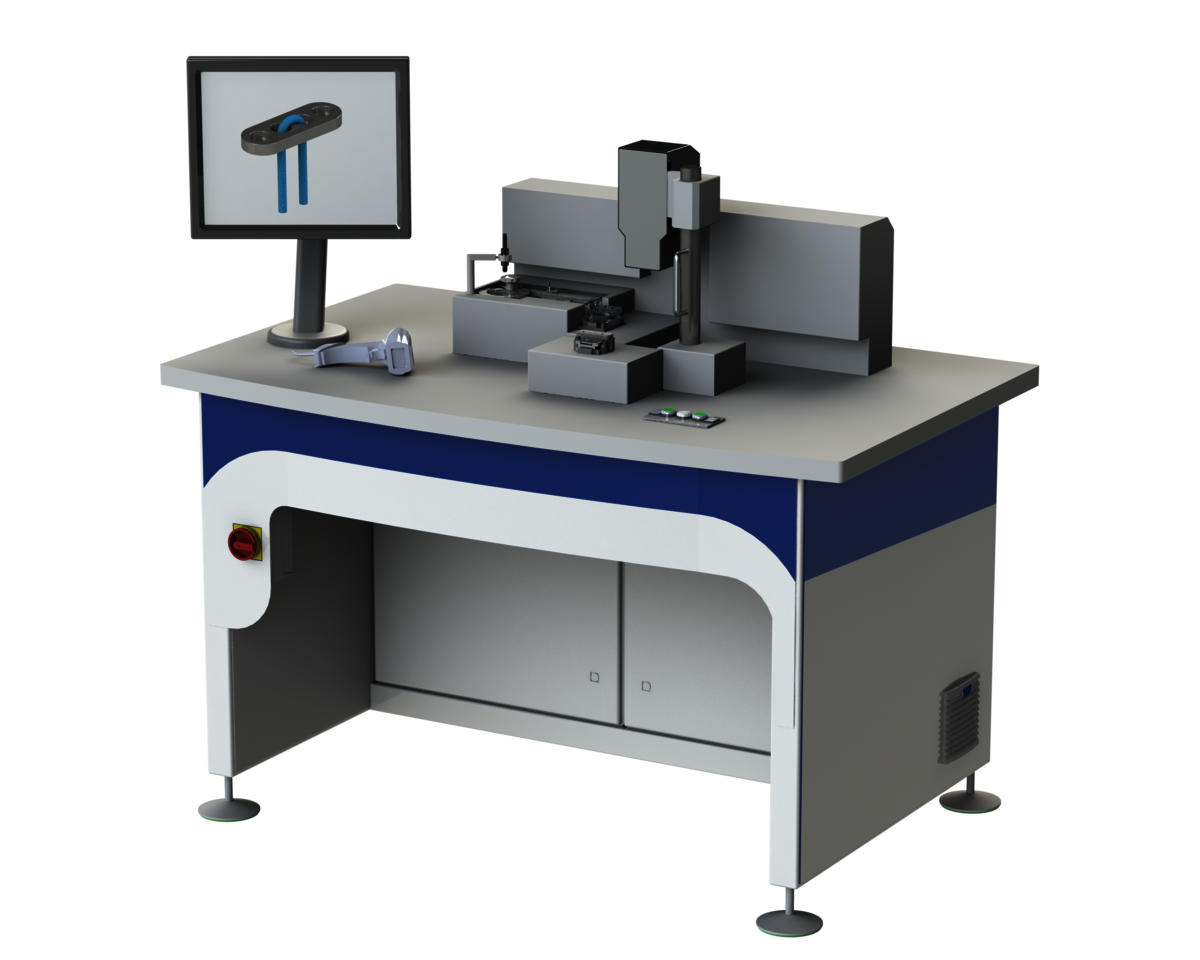

Banc intelligent d'assemblage contrôlé CIMED-SB.

Basé sur notre plateforme Smart-Bench standard CIMED-SB.

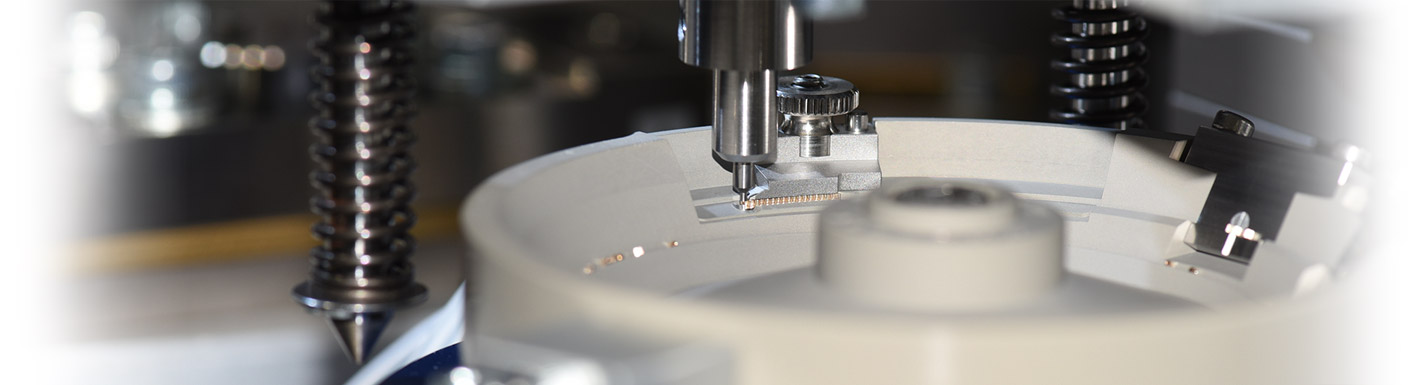

Alimentation manuelle, entièrement ou semi-automatique de composants à partir de 1,0 mm.

Modules et stations amovibles pour une large gamme de processus et d'applications.

Porte-pièces avec mécanismes actifs et systèmes de détrompage.

Exigences générales habituelles pour la répétabilité de positionnement des composants sur tout l'espace de travail ≤ ±25 μm.

Station de vision, avec logiciel pré-validé, pour :

- La reconnaissance, l'orientation, la mesure et le contrôle des pièces.

- L’assistance à l'opérateur (grossissement numérique).

- L’inspection finale.

Principaux procédés déjà implémentés :

- Assemblages mécaniques : chassage, sertissage, vissage, insertion.

- Assemblages par soudage : US, induction.

- Autres : collage, perçage, bobinage.

Tous types de matériaux traités : acier inoxydable, métaux, plastiques, verre, céramiques, matières organiques.

Large éventail d'applications dans le domaine des technologies médicales.

Assemblage contrôlé de :

Dispositifs médicaux implantables :

- Chirurgie du ménisque et de la colonne vertébrale.

- Stents, cathéters et électrodes.

- Chirurgie dentaire.

Implants actifs :

- Stimulateurs cardiaques et défibrillateurs.

- Pompes et valves.

- Neurostimulateurs.

Outils chirurgicaux.

USP

- Alimentation manuelle, entièrement ou semi-automatique en micro-pièces.

- Pour des pièces d'une taille à partir de 1,0 mm.

- Station de vision avec logiciel pré-validé.

- Répétabilité de positionnement sur tout l'espace de travail ≤ ±25 μm.

- Très large gamme d'applications.

Série d'équipements CIMED pour les applications MedTech :

- Bancs intelligents CIMED-SB.

- Conçus et construits pour être utilisés dans le domaine MedTech.

- Modules standards basés sur les directives GAMP®5.

- Cadre logiciel pour une validation CFR 21 part 11 plus facile et plus rapide.

- Des solutions adaptées et flexibles pour chaque étape de production.

- DFA, POC, lots de validation, petites et moyennes séries, grande production.

- Conception de base fiable, flexible et évolutive.

- Pour un large éventail d'applications et de processus MedTech.

Pour plus d'informations, CONTACTEZ NOUS

Pour être informé sur l'activité de Ciposa, inscrivez-vous à notre NEWSLETTER