BANC DE DOSAGE INTELLIGENT

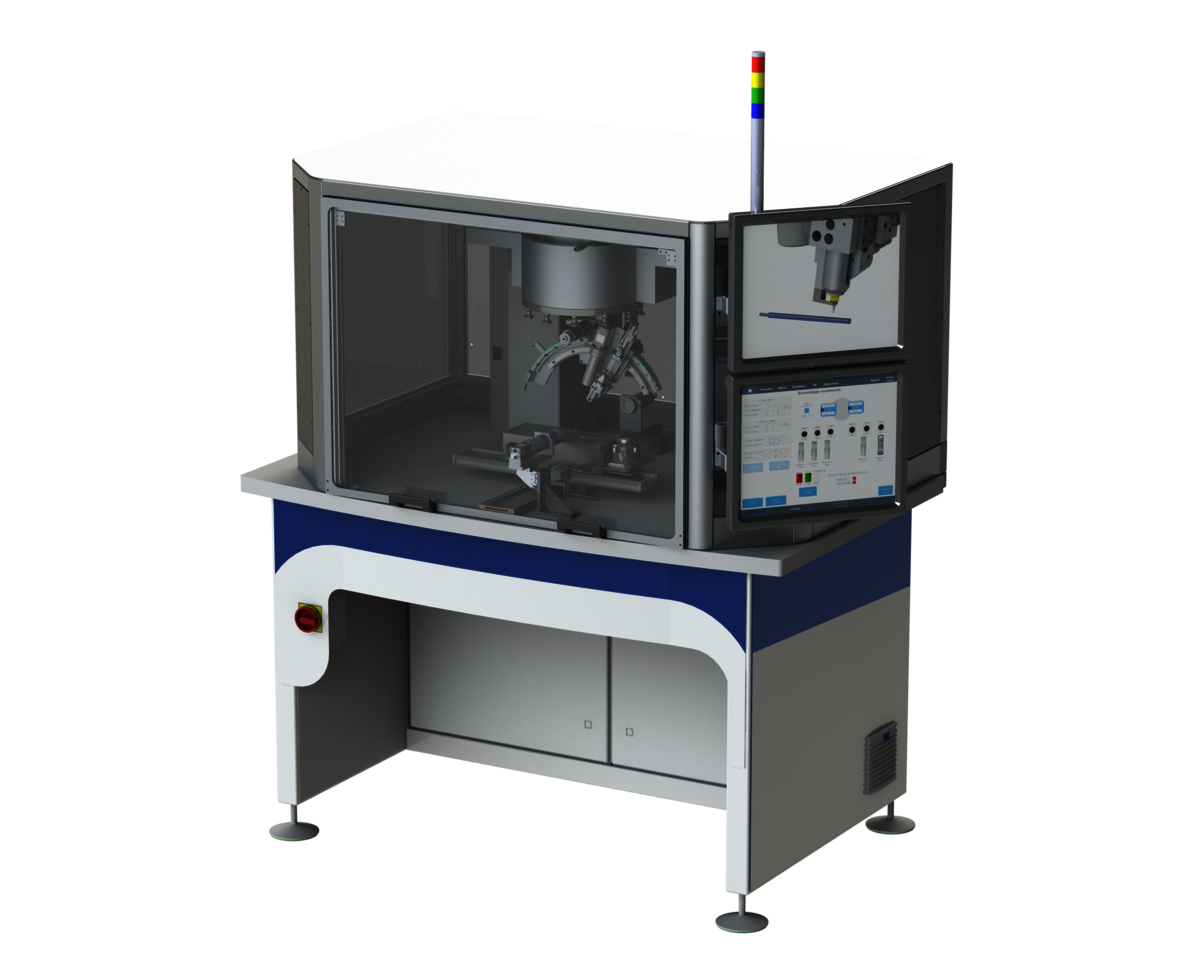

CIMED-SB Micro-Dispensing Smart-Bench.

Basé sur notre plateforme Smart-Bench standard CIMED-SB.

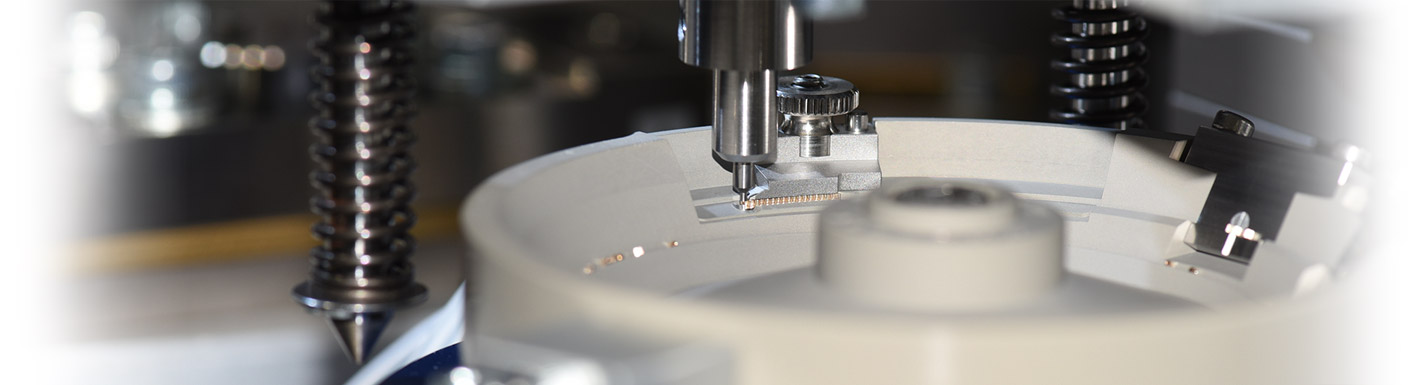

Tête de dosage jusqu'à 5 axes.

Système de vision embarqué sur la tête de dépose pour assurer :

- La reconnaissance/contrôle des composants avant le prélèvement.

- L'acquisition des positions X et Y des composants.

- Le servo-contrôle de la tête de dosage.

- Le contrôle final de la dépose > qualité et quantité.

Capteur laser sur l'axe Z pour l'acquisition des hauteurs des composants.

Répétabilité du positionnement final sur tous les axes ≤ ±10 μm.

Dosage très précis et répétable jusqu'à l'échelle du nanolitre.

Large gamme de systèmes de dosage disponibles :

- Temps/pression.

- Jetting.

- Volumétrique.

Volume minimum = 1,0 nL, avec une répétabilité de dosage ≤ ± 5,0 %.

Large éventail d'applications dans le domaine du Medtech.

Micro-dosage et dosage de :

Revêtements en silicone biocompatible.

- Revêtement d'implants et de stents.

Adhésifs et produits d'étanchéité.

- Jetting de colle pour l'encapsulation d'électrodes.

- Collage de valves péristaltiques.

Lubrifiants (huiles, graisses).

- Lubrification des éléments rotatifs dans la valve péristaltique.

USP

- Tête de micro-dosage jusqu'à 5 axes.

- Micro-dosage piloté par un système vision.

- Répétabilité du positionnement final sur tous les axes ≤ ±10 μm.

- Volume minimum = 1,0 nL.

- Répétabilité du dosage ≤ ± 5,0 % standard.

- Cadre logiciel pour une validation CFR 21 part 11 plus facile et plus rapide.

Série d'équipements CIMED pour les applications MedTech :

- Bancs intelligents CIMED-SB.

- Conçus et construits pour être utilisés dans le domaine MedTech.

- Modules standards basés sur les directives GAMP®5.

- Cadre logiciel pour une validation CFR 21 part 11 plus facile et plus rapide.

- Des solutions adaptées et flexibles pour chaque étape de production.

- DFA, POC, lots de validation, petites et moyennes séries, grande production.

- Conception de base fiable, flexible et évolutive.

- Pour un large éventail d'applications et de processus MedTech.

Pour plus d'informations, CONTACTEZ NOUS

Pour être informé sur l'activité de Ciposa, inscrivez-vous à notre NEWSLETTER